讓買家找上門

發(fā)布采購單》

正品保障

采購返現(xiàn)

源頭直供

讓買家找上門

發(fā)布采購單》

正品保障

采購返現(xiàn)

源頭直供

?

?

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

| FERRO Process Temperature Control Rings 660~1750℃ | |||||||||||||||||||||||||||||||||||||

| 測溫環(huán)特性: 很多高溫耐火產(chǎn)品在生產(chǎn)過程中需要測量窯爐溫度,但多數(shù)測量手段和工具在時間和空間上均受到限制。 例如:熱電偶并不能測量產(chǎn)品本身的溫度,而是產(chǎn)品燒制時的環(huán)境溫度。熱電偶記錄在頂端獲得的溫度,只是空間和時間的一點, 一個熱電偶無法決定加熱過程;一只熱電偶是無法提供窯爐在不同方位加熱是否均勻的信息,它只能測輻射熱,而不涉及來自窯爐 具的傳導熱。 FERRO 測溫環(huán)是一種高精密度的陶瓷溫度指示器,它忠實記錄了燒制過程中制品所經(jīng)歷的熱過程。 FERRO 測溫環(huán)不僅可以測出輻射熱與放射熱,還考慮了溫度隨時間推移所產(chǎn)生的影響。 FERRO 測溫環(huán)能方便地把受熱過程以一個簡單的數(shù)字來表示--環(huán)溫度(RT),便于應用在實際工作中。 |

|||||||||||||||||||||||||||||||||||||

| Process Temperature Control Rings Higher quality products and lower costs through improved, reliable firing control Take control of your firing process In the manufacture of ceramic products, few things are as critical as accurate control of the firing process. After all, the results have a direct effect on the quality - and the costs - of the final product. Optimal firing control requires both accurate measurement of the heat treatment - the temperature and its effect over time - together with the ability to control the temperature and the uniformity of its distribution throughout the kiln. Effective temperature measurement is the key to guaranteed product quality. Most conventional temperature measurement techniques are limited both in time and in location. For example, the thermocouples generally used in the ceramic industry do not measure the temperature of the product itself,but that of its vicinity. They are also limited to measuring radiated heat, and take no account of heat transferred from kiln furniture. |

|||||||||||||||||||||||||||||||||||||

廣東測溫環(huán) |

|||||||||||||||||||||||||||||||||||||

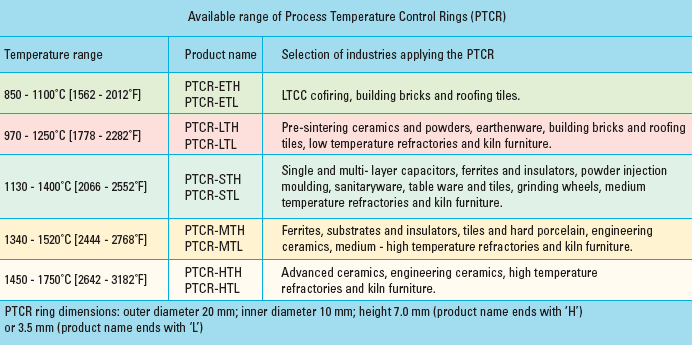

| FERRO Process Temperature Control Rings 陶瓷測溫環(huán)的型號及應用行業(yè) | |||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

| FERRO Process Temperature Control Rings 測溫環(huán)規(guī)格 | |||||||||||||||||||||||||||||||||||||

| PTCR測溫環(huán)尺寸: 外徑:20mm, 內(nèi)徑:10mm, 厚度:7.0mm。 PTCR為可靠的高精度產(chǎn)品,*大誤差小于3℃。甚至可達1.5℃。 產(chǎn)品包裝:15個/小紙盒、600個/大盒。 The multifunctional PTCR concept comprises • improved ceramic PTCR rings • improved, convenient packaging • the PTCR micrometer with numerical or digital read-out • a batch-specific temperature table PTCR: What it is The Process Temperature Control Ring, PTCR,is a highly accurate ceramic temperature indicator which records the true heat treatment received by the fired product. PTCR rings take account of both radiated and transferred heat, as well as the effects of temperature over time. It conveniently allows this recorded heat exposure to be expressed as a single number - ring temperature (RT) - which is practical and easy to work with. PTCR rings can be used in both batch and continuous tunnel kilns; they are used in a range of atmospheres*. Five different PTCRtypes are available - in heights of 3.5 and 7.0mm - covering a range from 850 to 1750°C(1562 to 3182°F). Ring types are identified by color coding and batch and type numberspressed into the ring. Originally PTCR has been developed for inhouse application in critical firing processes for advanced electronic ceramic components. Now, the PTCR brings the benefits of easy,accurate kiln temperature measurement to awide range of industries. PTCR: How it works When exposed to heat in the kiln, the PTCR ring contracts - and continues contracting as the top temperature is maintained over time. The degree of contraction is almost linear over the complete operating range of the PTCR,providing a practical measure of the accumulated heat to which the ring - and the fired products - have been subjected. The amount of contraction - the amount by which the ring diameter has shrunk - is measured with a numerical or digitalmicrometer. This measurement can be converted to 'ring temperature' for ease of comparison and correlation to the firing process. PTCR: Quality you can rely on PTCR is recognized for its accuracy and reliability, and its recently improved technology now offers an unsurpassed accuracy guarantee: a minimum variation of 3°RT. ** This reliability is based on a stringent manufacturing process. PTCR rings are made from a mix of high-grade materials. Their composition is fine-tuned through advanced Design Of Experiments- (DOE) techniques, and the production process itself is controlled by Statistical Process Control. In fact, the entire PTCR manufacturing facilities have been awarded the internationally recognized ISO 9001:2000 and ISO 14001 quality certification.  |

|||||||||||||||||||||||||||||||||||||

| FERRO PTCR測溫環(huán)工作原理及使用方法: | |||||||||||||||||||||||||||||||||||||

| 1、FERRO PTCR測溫環(huán)具有公認的準確性和可靠性,測溫環(huán)幾乎可被放置在窯爐的任何位置,爐體內(nèi)、推板或傳輸帶上 ,在使用前,不必測量溫度; 2、FERRO PTCR陶瓷測溫環(huán)的工作原理是根據(jù)其在工作溫度范圍內(nèi)的線性收縮,從而給出測溫環(huán)和燒成品的實際累計熱量,對照換算表得出測試溫度,燒制結束后,將測溫環(huán)取走并做記號; 3、FERRO PTCR陶瓷測溫環(huán)在窯爐中受熱時,它就收縮,并在*高溫度隨保溫時間延長而繼續(xù)收縮。 在其使用溫度范圍內(nèi),收縮率是線性的,這為FERRO陶瓷測溫環(huán)和被燒制的產(chǎn)品所受到的加熱量提供了一種實用的測量方法;收縮量(環(huán)直徑的減少)可用數(shù)字 千分尺測量 ,使用的手持數(shù)字千分尺記錄每一片測溫環(huán)的直徑,準確 到0.01mm; 4、參照包裝上所附的 環(huán)外徑與溫度對照表、溫度校正曲線圖(隨產(chǎn)品提供),所測出的測溫環(huán)直徑可轉(zhuǎn)換成 等效溫度。 注意:為了使用時準確和方便FERRO測溫環(huán) 每個溫度表都是為該批測溫環(huán)而特別制定的,所標的生產(chǎn)批號必須與溫度 對照表上的保持一致。 |

|||||||||||||||||||||||||||||||||||||

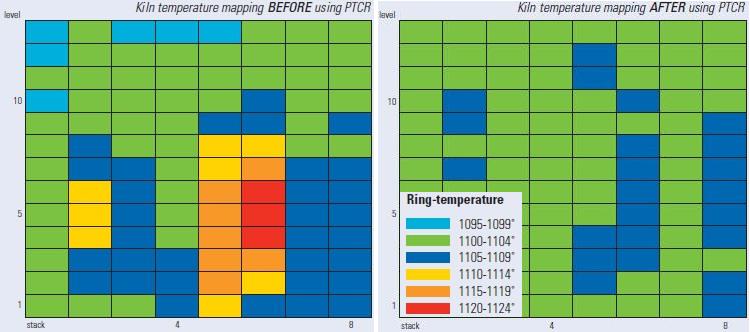

| PTCR in practice: accuracy and convenience Firing process optimization In the process of establishing a standard, the firing process is characterized by 'mapping' the ring temperatures of PTCR rings distributed throughout the kiln. This allows the 'hot' and 'cold spots' to be detected and defined. Using the heat treatment mapping, the firing process can then be optimized by offsetting heat sources or thermocouples as indicated by the variations in ring temperatures. As a rule of thumb, one degree of ring temperaturecorresponds to one degree Celsius. The exact relationship between ring temperature and degrees Celsius is of course dependent upon the specific firing cycle of the kiln. The adjoining illustration shows two heat treatment mappings of the same 15m3 kiln. The first was generated before using thePTCR; the second, after firing process optimization using PTCR rings, resulting in substantial yield improvement. |

|||||||||||||||||||||||||||||||||||||

| Firing process control In the course of time - as a result of aging of the heating elements or frequently alternating firing cycles - 'hot' and 'cold spots' maygradually return to the kiln.The PTCR can help here, too. once the firing process has been optimized, PTCR rings can be used regularly to monitor the firing process and to detect these deviations as they gradually arise, before they affect product quality. By comparing the current ring temperatures against the defined standard, the number of degrees of ring temperature by which the firing process must be adjusted can be determined. Using several rings at critical locations in the kiln ensures that an even heat distribution is maintained. Quality control at lower cost Besides the benefits of yield improvement through optimization of the firing process, the PTCR can also help reduce production costs.Simple comparison of ring temperature against a quality standard indicates whether the products are sintered to specification.Expensive, time-consuming conventional quality checks - destruction testing, geometry,density and porosity tests - can be reduced or eliminated. |

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

| Method of use Positioning PTCR rings can be placed at almost any location in the kiln, on kiln furniture, trolleys or transports. The use of both multi-location and multi-level positioning is recommended, as this provides the most insight into the heat treatment distribution within the kiln. Measuring The contraction of the PTCR diameter reflects the actual heat treatment at the point where the ring was located in the kiln. The diameter is easily measured using a PTCR micrometer - only a single measurement is required (as shown). PTCR micrometers Numerical (N) and Digital(D) have an integral, ergonomically designed solid base with a ring positioning chuck, which ensures the ring is always correctly positioned in the micrometer. This design not only simplifies the measuring process, but also improves the repeatability and reproducibility of ring temperature measurement. Converting to ring temperature The measured ring diameter is converted to ring temperature using the conversion table enclosed in each packing unit. Each table is specific to the particular batch of rings, for accuracy and convenience.The ring temperature is a practical single number which is useful for comparison purposes - for instance to relate the recorded heat treatment to the firing process and defined standards - so that any required adjustments can be made. It does not necessarily reflect the actual kiln temperature; the PTCR acts as an accumulator, measuring the total heat treatment over time, rather than the maximum temperature attained. Establishing a standard ring temperature In order to make ring temperature comparisons between different firings, a standard ring temperature must be defined. This is done by including PTCR rings in a series of firings, and relating their ring temperatures to the quality of the products produced. The ring temperature which corresponds to products fired to the correct specifications can be used as the standard. |

|||||||||||||||||||||||||||||||||||||

|